READING THE RECIPE

A great beer starts with a great recipe!

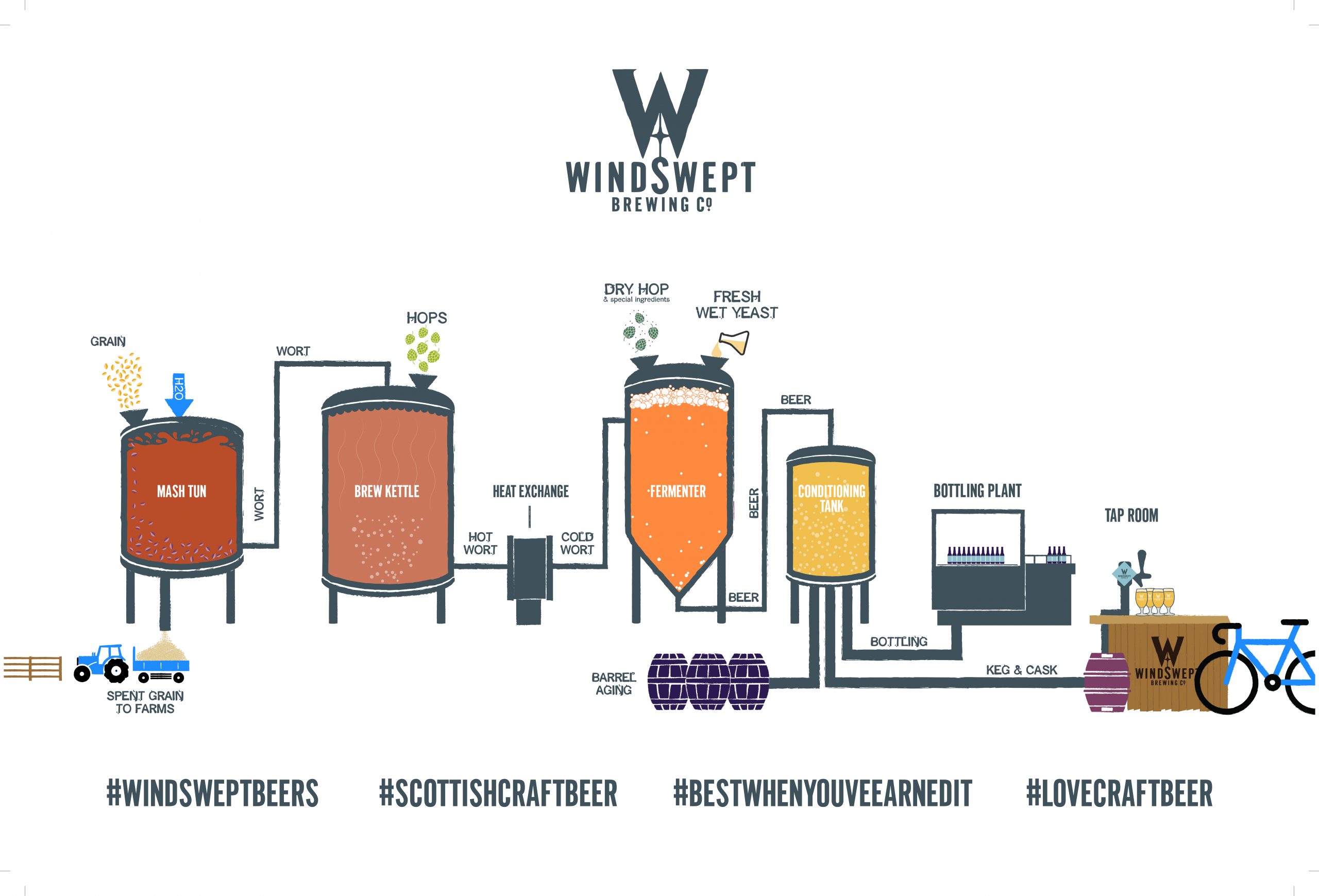

It usually takes us about six months from initial concept, through trials and taste testing before we arrive at a recipe we are happy with. The recipe for Hurricane was developed back in 2017 and first brewed in March 2018…not long after Stuart, our Head Brewer, joined Windswept.

We tend to do all of the preparation for a brew a day or two before any actual brewing takes place. Even when you’re a seasoned pro like our Stuart the process always starts with reading the recipe.

MARVELLOUS MALT

First we measure out the malt. Just like hops, the malt we use is chosen to suit each beer style and where possible we will try and source Scottish grown grains.

For Hurricane we use two different types of malt: Pale malt, a type of barley malt, and Wheat malt. Pale Malt contains most of the sugary goodness needed for the brew. Wheat malt, which contains higher levels of protein than barley malt, is added mostly for good head retention on your pint and increased mouthfeel.

Once weighed out (with military precision) the malt is added to the Grist Hopper.

JUST A TOUCH OF SALT

Here in Moray, the heart of whisky country, we are blessed with fantastic Speyside water but each brew needs different water profiles to achieve the perfect taste. So at this stage in Hurricane brew prep, we add a blend of powdered salts to the malt to achieve the right pH balance. Historically breweries were limited in the types of beer they could brew based on the water hardness in their area but over time developments in science and brewing techniques has led to great brewing flexibility using these salt compounds.

Once the salt has been added, the grain can sit in the Grist Hopper until we are ready to start the brew.

THINGS ARE HEATING UP

Lastly, we make sure that the fill level and temperature of the Hot Liquor Tank (HLT) are set correctly, ready for mashing in.

For our most popular beers we tend to do large 20 barrel brew each time – that’s the equivalent of 5200 glorious pints. To make it more manageable for the team, we split the brew over two days with 10 barrels being brewed on the first day and then 10 barrels on the second. This means that once we have mashed in the first lot of grain, we repeat the whole preparation process so we are ready brew again the next day.

Brewing life is certainly a busy life!

Check back next week as we mash in!

Subscribe to our newsletter with stories from our latest adventures and the best beer tips

Windswept Brewing Co. Ltd. Company No. SC415555. VAT No. 137744690. All rights reserved.

AWRS No. XZAW00000100350

Windswept Brewing Co. Ltd. Company No. SC415555. VAT No. 137744690. All rights reserved.

AWRS No. XZAW00000100350